Industry 4.0, the fourth industrial revolution, has begun. Manufacturing industries are going through disruptive change through digital transformation and the use of exponential technologies. The concept has received a great deal of hype in recent years, yet remains an abstract idea for many businesses and entrepreneurs.

What is Industry 4.0?

Over the past two and a half centuries, a series of industrial revolutions have transformed how manufacturers produce goods. They are namely,

Just as these revolutions have forever changed how the world manufactures widgets, Industry 4.0 promises to have the same transformational impact.

While Industry 3.0 focused on the automation of individual processes and machines, Industry 4.0 focuses on the end-to-end digitization of all physical assets and their real-time integration into digital ecosystems with value chain partners.

The seamless generation, extraction, and analysis of the resulting data underpin the efficiency gains promised by Industry 4.0. Specifically, it empowers businesses to understand better and control the various dimensions of their production and operation.

This insight allows businesses to leverage instant data insights to boost productivity, improve process efficiencies, and drive the business bottom line.

At its heart, Industry 4.0 leverages the inter-connectivity among a wide range of technologies to ultimately create value and offers a more comprehensive, interlinked, and holistic approach to manufacturing.

Technologies Driving Industry 4.0

Industry 4.0 is no longer a ‘future trend’ – for companies that are at the forefront of driving change and innovation; it is now at the heart of their strategic and research direction. The following seven technology trends often referred to as exponential technologies, form the building blocks of Industry 4.0.

Big Data, Analytics & AI

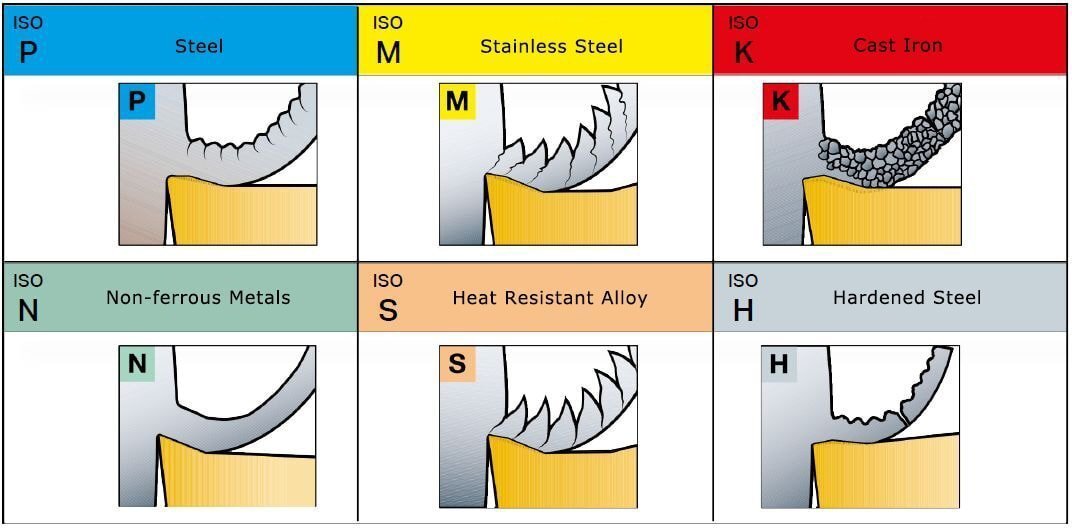

Industry 4.0 generates an enormous amount of data. The extraction, processing and analysis of data from multiple sources (production equipment, processes, enterprise, and customer management systems) are becoming standard in generating insights, supporting real-time decision making and improving existing processes and business parameters.

Augmented Reality (AR) and Wearable Technology

Augmented-reality-based technologies can have a far-reaching impact on processes, including training and walkthroughs, part selection, and remote repair and troubleshooting capabilities.

Although these technologies are still in their infancy, companies are looking at a broader use of AR to provide workers with real-time information to improve decision making and minimize human performance errors.

Hence, reducing a lot of overhead costs associated with transportation and workforce management.

Internet of Things (IoT) and Smart Sensors

Field devices are being equipped with embedded computing, allowing them to communicate and interact both with one another and with centralized controllers. This move will also decentralize analytics and decision making, enabling real-time responses.

By monitoring, controlling, and orchestrating large amounts of different devices. IoT has many use cases, with asset management and tracking being one of its major applications. For example, IoT can be used in inventory management - to track and eventually prevent the overstocking or understocking of inventory.

Additive Manufacturing

With Industry 4.0, additive-manufacturing methods, such as 3-D printing, are being widely adopted to produce small batches products that offer construction advantages, such as intricate, lightweight designs and will enable rapid prototyping, and greater individualization and customization.

Additionally, certain advances in the technology have even stretched its application in metal part manufacturing without the need for tooling.

Cloud Computing

Cloud-based applications offer excellent opportunities to host, share, and run the analysis of the big data generated by Industry 4.0. At the same time, the performance of cloud technologies will only further improve with time and scalability, achieving reaction times that will be multiple folds better than local or traditional computing technologies. Cloud computing enables inter-connectivity and distribution not only between factories but also across the entire global value chain network.

Horizontal and Vertical Integration

With Industry 4.0, companies, departments, and their functions and capabilities will become much more cohesive, as cross-company, universal data-integration networks evolve and enable truly automated value chains.

Horizontal integration stretches well beyond just the internal operations from suppliers to customers and all the key-value chain partners. It now includes technologies from track and trace devices to real-time integrated task planning and execution. A system based, end-to-end real-time planning and horizontal integration and collaboration are now possible using cloud-based platforms.

Vertical integration includes that within a network of manufacturing sites, including digital engineering and real-time data integrated production planning. Horizontal and vertical integration is the glue that binds together the technology frontiers.

Cybersecurity

With the increased connectivity and more touchpoints where is data collected means that the need to protect critical production and safety systems from cybersecurity threats increases dramatically, and the role of cybersecurity for an organization’s business continuity becomes imperative.

Per a PwC study, business owners flagged concerns such as operational interruption and liability risks at the top of their list for data security concerns.

Industry 4.0: Success Stories

A BCG study on Industry 4.0 in Singapore, claims, that rapid adoption of Industry 4.0 could boost the country’s labor productivity by about 30%, create 22,000 new jobs with average salaries up to 50% higher compared to current, and add S$36B in total manufacturing output and revenues for companies including MNCs and local firms, all by 2024. However, this study does appear to state the ideal trajectory and somewhat over-optimistic; these success stories that demonstrate that the targets are within reach.

Rio Tinto, one of the world’s largest mining companies, were able to recover up to $2M in losses due to unexpected asset failures by installing 200 sensors that monitored every facet of their vehicle feet 24/7. By combining smart sensors with data analytics, there were able to proactively identify problematic trucks remotely and plan maintenance and productivity around their production schedule.

Japanese engineering and automobile OEM company, HIROTEC Corporation, had incurred up to $1.3M in costs due to unplanned downtime. They managed to deploy an on-premise IoT cloud platform with edge analytics, which they claim led to a “100% reduction in time to manually inspect production systems, enabling technicians to re-invest that time in tasks that drive more value to production workflows”.

General Electric (GE) offers us a glimpse of how Augmented Reality can empower manufacturing quality control and human performance error minimization. Through its pilot program at its jet engine manufacturing facility in Cincinnati, OH, USA, GE implemented AR glasses for their workers. This program allowed the workers to view digitized work instruction without disruption of work activities as well as access to training videos or remote voice commands from subject matter experts.GE reported up to an 11% improvement in worker productivity as well as quality.

Conclusion

Industry 4.0 has ushered in a digital economy where technology is ubiquitous, driving transformative change in the way we live and radically disrupting every business sector.

These new technologies might be exciting, but the real lingering challenge of Industry 4.0 is that the majority of companies are still not ready to use them.

Even as technological transformations continue apace and early adopters reap the benefits of the technologies that suit their business context, executives at most companies are still bewildered by the vast array of technologies and capabilities already available. It is difficult for these executives to see an obvious entry point as prevalent myths and misconceptions can cloud anybody’s judgment.

In our next article, we will cover some of the myths, challenges, strategies, and implementation of Industry 4.0 principles in your business.