Lathe machines create sophisticated parts for medical, military, electronics, automotive, and aerospace applications. Read on to find out the top 10 machining operations performed on a lathe.

A lathe is capable of performing numerous machining operations to deliver parts with the desired features. Turning is a popular name for machining on a lathe. Nevertheless, turning is just one kind of lathe operation.

The variation of tool ends and a kinematic relation between the tool and workpiece results in different operations on a lathe. The most common lathe operations are turning, facing, grooving, parting, threading, drilling, boring, knurling, and tapping.

This post is a follow-up to our 9 Milling Operations You Need To Know on a Lathe. If you’re new to the world of mills and cutters, this one’s for you.

1. Turning

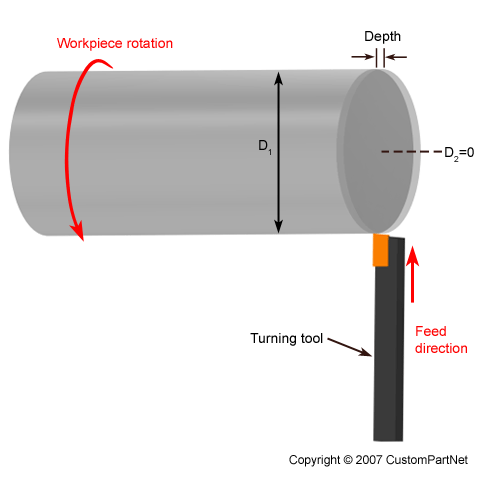

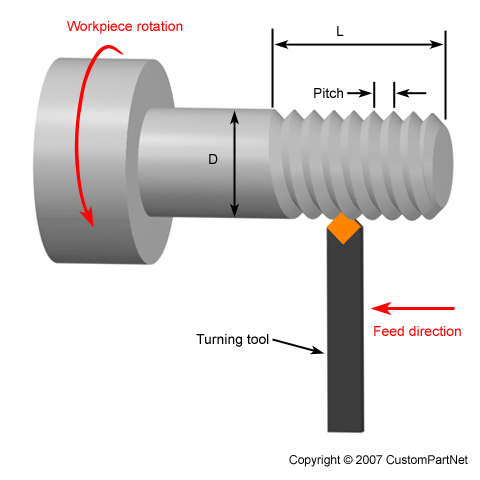

Turning is the most common lathe machining operation. During the turning process, a cutting tool removes material from the outer diameter of a rotating workpiece. The main objective of turning is to reduce the workpiece diameter to the desired dimension. There are two types of turning operations, rough and finish.

Rough turning operation aims to machine a piece to within a predefined thickness, by removing the maximum amount of material in the shortest possible time, disregarding the accuracy and surface finish. Finish turning produces a smooth surface finish and the workpiece with final accurate dimensions.

Different sections of the turned parts may have different outer dimensions. The transition between the surfaces with two different diameters can have several topological features, namely step, taper, chamfer, and contour. To produce these features, multiple passes at a small radial depth of cut may be necessary.

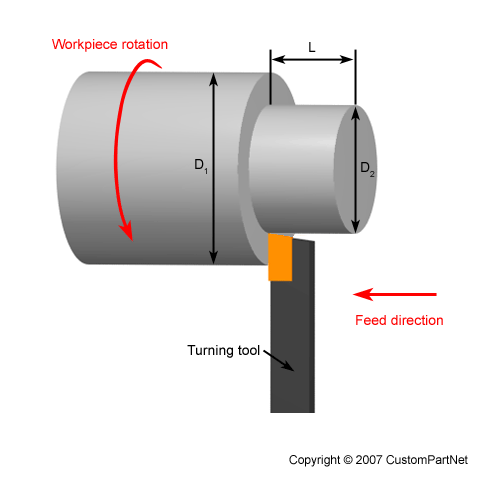

Step Turning

Step turning creates two surfaces with an abrupt change in diameters between them. The final feature resembles a step.

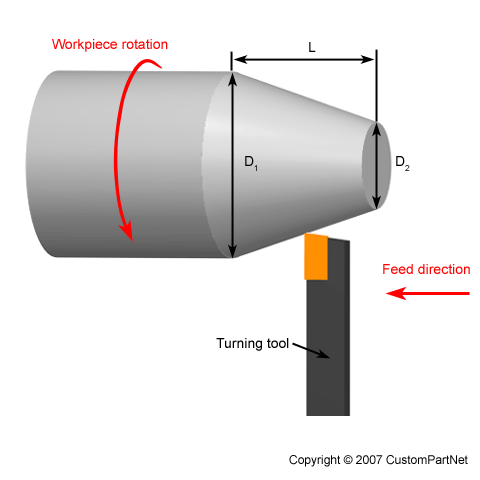

Taper Turning

Taper turning produces a ramp transition between the two surfaces with different diameters due to the angled motion between the workpiece and a cutting tool.

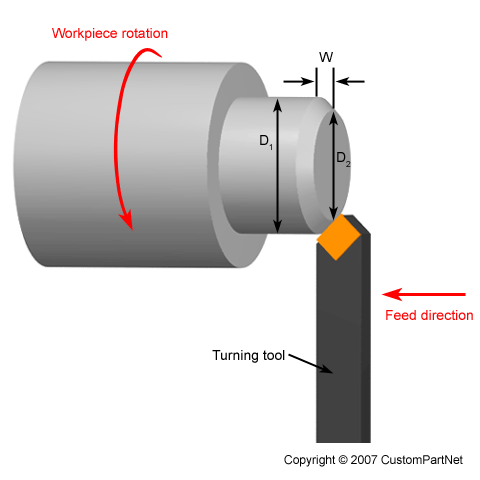

Chamfer Turning

Similar to the step turning, chamfer turning creates angled transition of an otherwise square edge between two surfaces with different turned diameters.

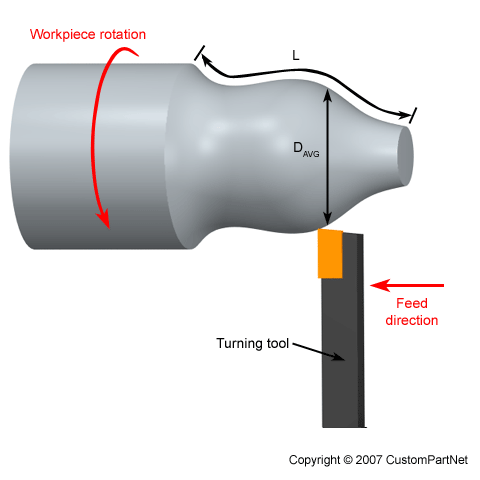

Contour Turning

In contour turning operation, the cutting tool axially follows the path with a predefined geometry. Multiple passes of a contouring tool are necessary to create desired contours in the workpiece. However, form tools can produce the same contour shape is a single pass.

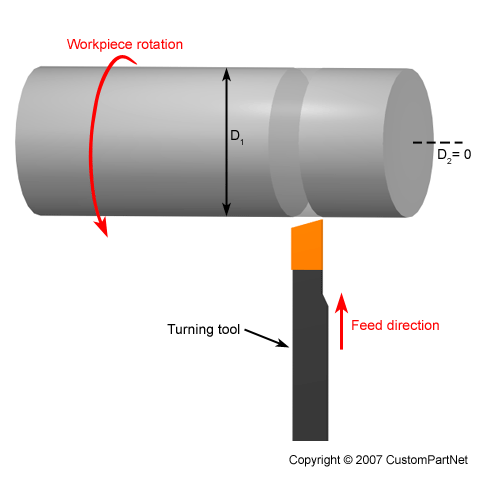

2. Facing

During the machining, the length of the workpieces is slightly longer than the final part should be. Facing is an operation of machining the end of a workpiece that is perpendicular to the rotating axis. During the facing, the tool moves along the radius of the workpiece to produce the desired part length and a smooth face surface by removing a thin layer of material.

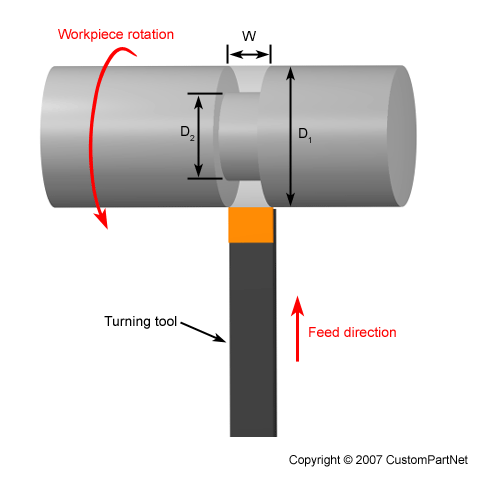

3. Grooving

Grooving is a turning operation that creates a narrow cut, a "groove" in the workpiece. The size of the cut depends on the width of a cutting tool. Multiple tool passes are necessary to machine wider grooves. There are two types of grooving operations, external and face grooving. In external grooving, a tool moves radially into the side of the workpiece and removes the material along the cutting direction. In face grooving, the tool machines groove in the face of the workpiece.

Want to dive deeper into how chips behave during cutting? Check out our guide on chip formation and chip breaking in machining.

4. Parting

Parting is a machining operation that results in a part cut-off at the end of the machining cycle. The process uses a tool with a specific shape to enter the workpiece perpendicular to the rotating axis and make a progressive cut while the workpiece rotates. After the edge of the cutting tool reaches the centre of the workpiece, the workpiece drops off. A part catcher is often used to catch the removed part.

5. Threading

Threading is a turning operation in which a tool moves along the side of the workpiece, cutting threads in the outer surface. A thread is a uniform helical groove of specified length and pitch. Deeper threads need multiple passes of a tool.

6. Knurling

Knurling operation produces serrated patterns on the surface of a part. Knurling increases the gripping friction and the visual outlook of the machined part. This machining process utilizes a unique tool that consists of a single or multiple cylindrical wheels (knurls) which can rotate inside the tool holders. The knurls contain teeth that are rolled against the surface of the workpiece to form serrated patterns. The most common knurling pastern is a diamond pattern.

7. Drilling

Drilling operation removes the material from the inside of a workpiece. The result of drilling is a hole with a diameter equal to the size of the utilized drill bit. Drill bits are usually positioned either on a tailstock or a lathe tool holder.

8. Reaming

Reaming is a sizing operation that enlarges the hole in the workpiece. In reaming operations, reamer enters the workpiece axially through the end and expands an existing hole to the diameter of the tool. Reaming removes a minimal amount of material and is often performed after drilling to obtain both a more accurate diameter and a smoother internal finish.

9. Boring

In boring operation, a tool enters the workpiece axially and removes material along the internal surface to either create different shapes or to enlarge an existing hole.

10. Tapping

Tapping is the process in which a tapping tool enters the workpiece axially and cuts the threads into an existing hole. The hole matches a corresponding bit size that can accommodate the desired tapping tool. Tapping is also the operation used to make a thread on nuts.

Curious how different stainless steels affect your machining? Learn the key differences between Type 303 and Type 304.

Conclusion

Lathes are capable of machining pieces with sophisticated features. The final part features are produced by the utilization of various tools and by changing the kinematical relationship between the cutter and a workpiece. In this article, we explained ten different lathe operations.

We at Turntech Precision provide the top quality parts machined on the Swiss-type lathes utilizing turning, facing, grooving, threading, knurling, boring, and tapping operations. We work closely with our customers to provide them with the best solution to their engineering problems in a variety of industries. Contact us today with your inquiries.